Now for the next turnover. The hull is quite a bit heavier now, with all the additions and finishes, but still easily manageable with two people.

In order to get the working height comfortable, I invested in four BEKVÄM step stools from IKEA. How they do these for £14 each, I don’t know! Even at the current price, they are a bargain, and will come in handy for many things in the future.

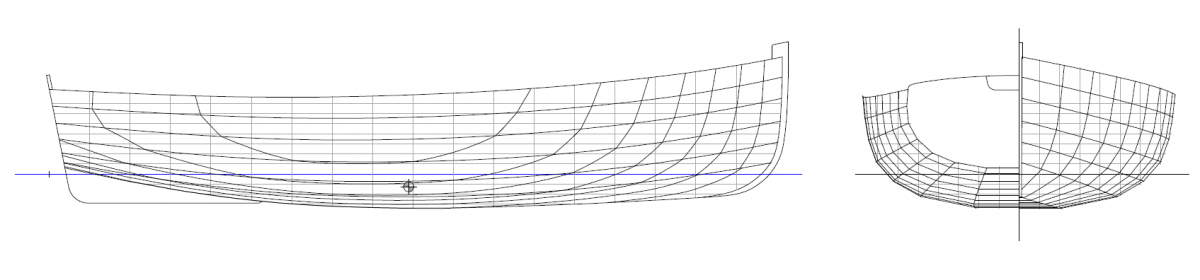

With one at each corner, it was then easy to level up the hull with small chocks, until the proposed waterline was level.

Next job is to cover the sole and garboard strakes with 30gsm matting, to make the bottom really robust for possible beaching on East Head. You’ll need some sacrificial rollers, and plenty of epoxy. It’s probably best to use the 206 slow hardener, otherwise this will become unworkable quite quickly in the summer months.

Yes I know I should use gloves but it was so hot, even in a wifebeater shirt!

Note the Bekvam stools

After the second coat of epoxy, the finish is surprisingly smooth, even taking into account the tapes already on the sole joint.

Next up, fit the skeg. This is a bit fiddly, as it needs to be aligned first, and then drilled from underneath – it’s useful to have a friend to hold it in place while you drill the pilot holes. Once fitted, the skeg is filleted both side, to make a really strong joint

Note how smooth the bottom is, even before any sanding and preparation